Adjustable Glass Twist

and Foot Pedal Jog

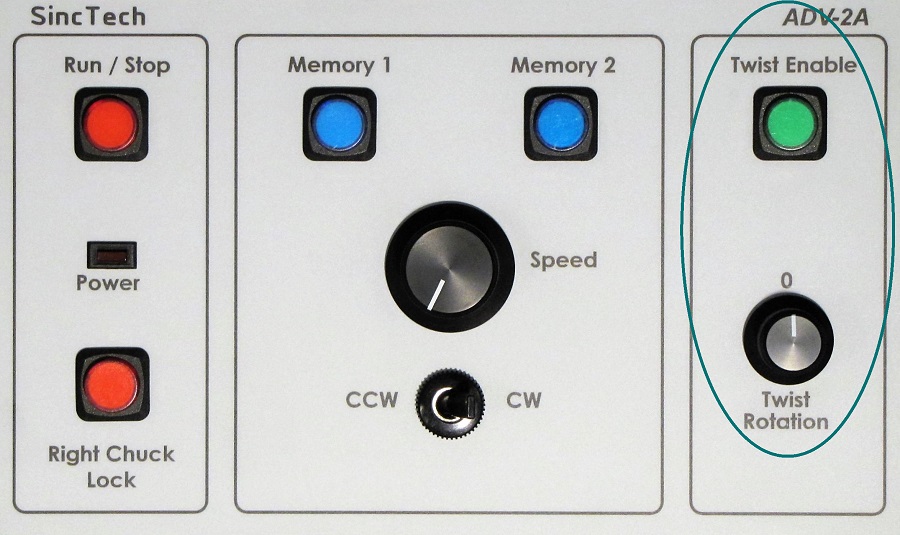

The two spindles of a glass lathe are typically locked in synchronization, however the Model ADV is no typical lathe. When the Twist feature is enabled, the lathe can slowly twist the molten glass while both lathe chucks are spinning at their normal RPM. The rate and direction of twist is adjustable and can be preset or even adjusted on the fly. The twisting action starts and stops under the control of a foot pedal to give you maximum use of your hands. When the foot pedal is not depressed, the lathe operates normally. When the foot pedal is depressed, the twisting action begins and continues until the foot pedal is released.

When not twisting glass the Foot Pedal Jog feature is available. With the lathe speed set to zero and the Twist feature disabled, depressing the foot pedal will cause the two lathe chucks to jog (turn slowly in synchronization) while the pedal is depressed. The Jog stops when the foot pedal is released. The lathe will jog in the direction as set on the lathe CCW/CW switch.

Scroll down for more Controller Features

OR

Return

Speed Memories

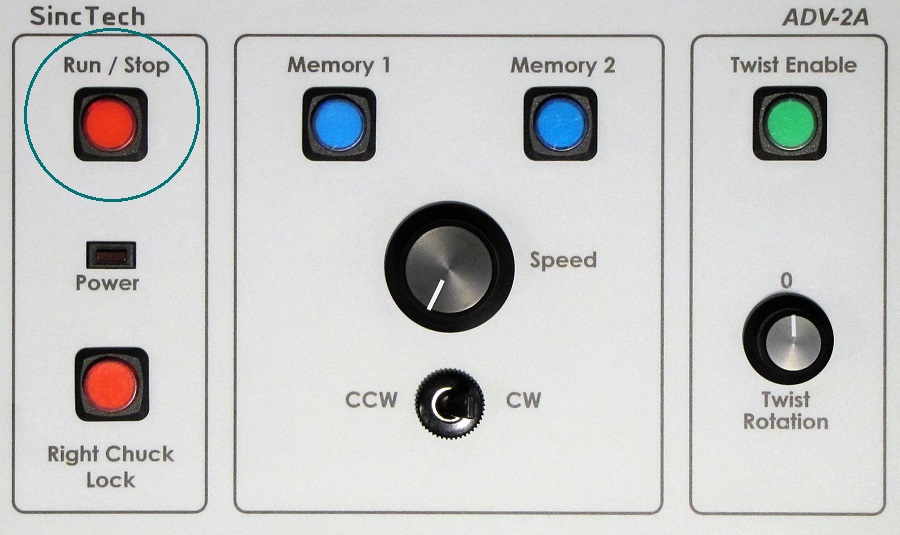

This Feature allows the user to store two different lathe speeds into the computer memory of the Model ADV. They are easy to store and can be recalled at the push of a button which will automatically return the lathe to your favorite speed. The Model ADV will remember your memory speeds for future use even if you remove power from the lathe.

Additionally full manual control of the lathe speed is always available using the Speed knob and direction control switch.

Scroll down for more Controller Features

OR

Return

Right Chuck Lock

The right chuck can be locked in a non-moving position while the left chuck remains fully operational. This allows you to use the right chuck to hold glass working tools to assist in working on your project. The lathe will stay in this mode until you change it, even if you remove the power.

Scroll down for more Controller Features

OR

Return

Run / Stop

In the Run mode the chucks are locked in synchronization with powerful stepper motors under the control of the internal computer. If the speed is set to zero, the chucks are stationary and held into place. Any time the Stop mode is enabled, the chucks are “de-clutched”, disconnected from motor control, and independently free turning while the computer enters into standby mode. This is particularly handy for setting up work, when aligning the lathe, or when you need to stop the lathe in a hurry for safety reasons.

Scroll down for more Controller Features

OR

Return

Systems Monitor

The internal computer control does more than just allow exciting new features. There are also a series of internal system checks happening to help make sure everything is operating correctly. This includes helpful audio signals and safety warnings. For example, if you power on the lathe with the manual speed knob not set to zero, the lathe will first give you a warning tone to let you know it will momentarily spin up the spindles.

Scroll down for more Controller Features

OR

Return

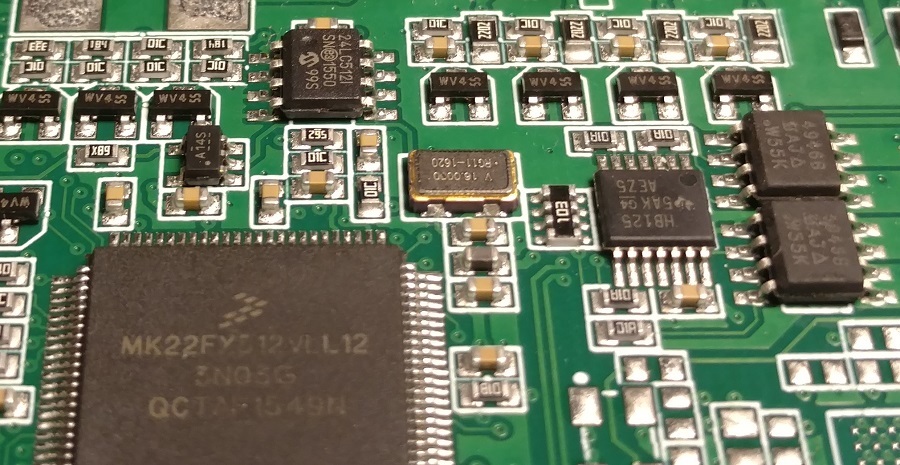

Advanced Motor Control

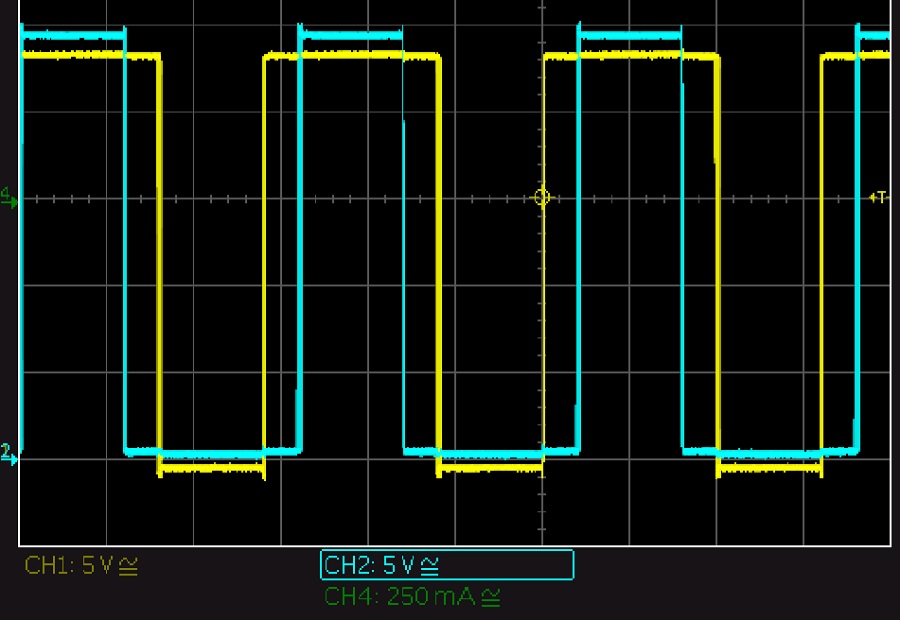

The internal computer automatically synchronizes two stepper motors, one for each chuck. Cutting edge drive algorithms keep these extra powerful high torque motors running cooler for less motor stress and longer life. The Model ADV motor drive system allows for whisper quiet and cool running when the stepper motors are stopped at full holding torque.

Scroll down for more Controller Features

OR

Return

Program Port

The primary purpose of this port is programming and testing of the Model ADV computer at the factory. However, the presence of this port will allow for downloading of any field updates as well as the ability to add any improved or new features in the future.