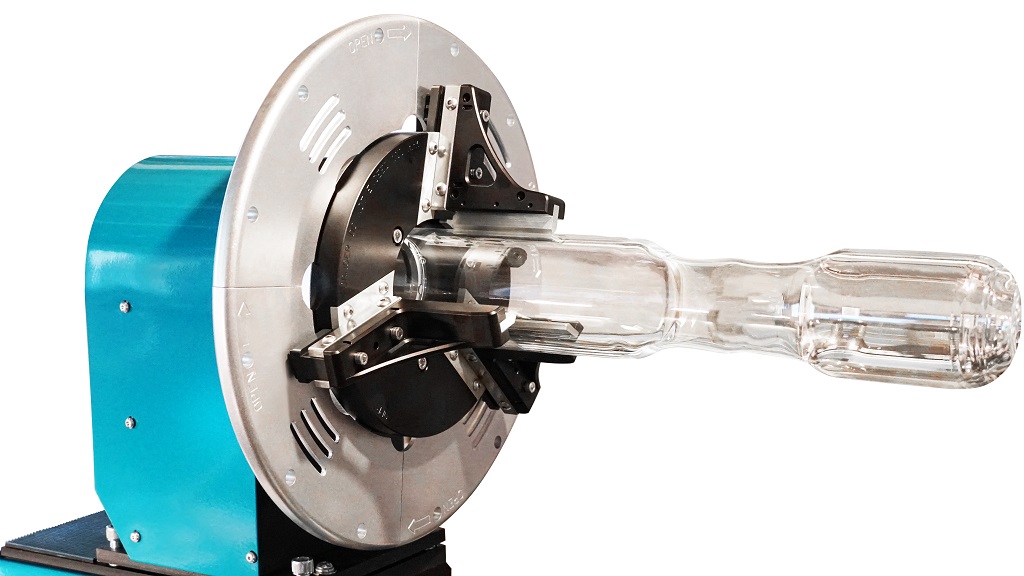

Premium Cygnet Aerospace Chucks

Two premium chucks are included in the purchase price of our lathe (a $4000 retail value). These chucks provides for a large 9″ radial swing and include a chuck jaw locking thumbscrew . These extra large chucks open to hold glass tubes up to 120mm (4.75″) and are excellent for use with large, heavy, and thick walled tubing.

Scroll down for more Design Features

OR

Return

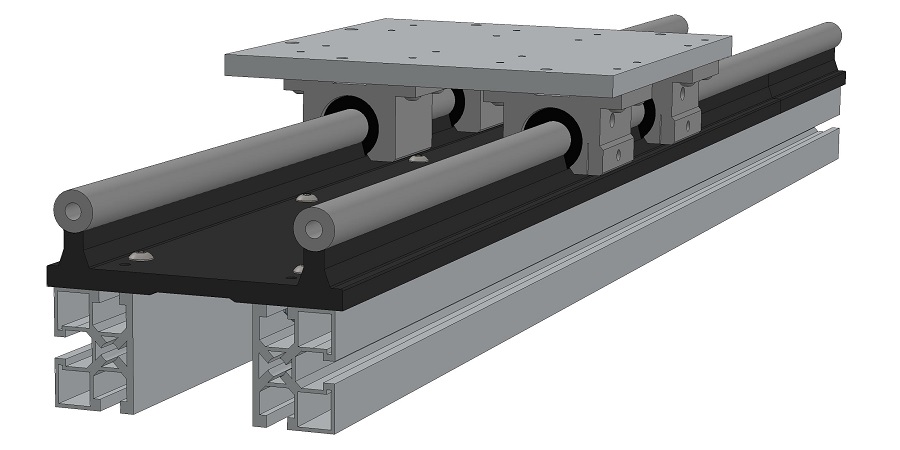

Bearing Selection

Each spindle is supported by two oversized precision tapered roller bearings to assure smooth operation and long lifetime. The sliding tailstock rides on four self-aligning recirculating linear ball bearing bushings. All these USA made bearings include an adjustable preloading system to assure zero clearance tolerances for accurate and precise glass work.

Scroll down for more Design Features

OR

Return

Frame Strength

The Model ADV consists of tough, high quality components held together by a rigid frame. The tail stock sliding rails are supported by a 0.3″ solid metal plate on top of twin structural beams. All other base frame components are 3/4″ thick solid metal. This approach has resulted in a high strength frame without excessive weight or waste of material.

Scroll down for more Design Features

OR

Return

Six Axis Alignment

Chuck alignment is critical for high quality glass work. Each spindle can be adjusted using the multi-axis alignment system built into both the Head and Tailstock. Our lathes are shipped pre-aligned to minimize set up efforts and get you up and running as fast as possible.

Scroll down for more Design Features

OR

Return

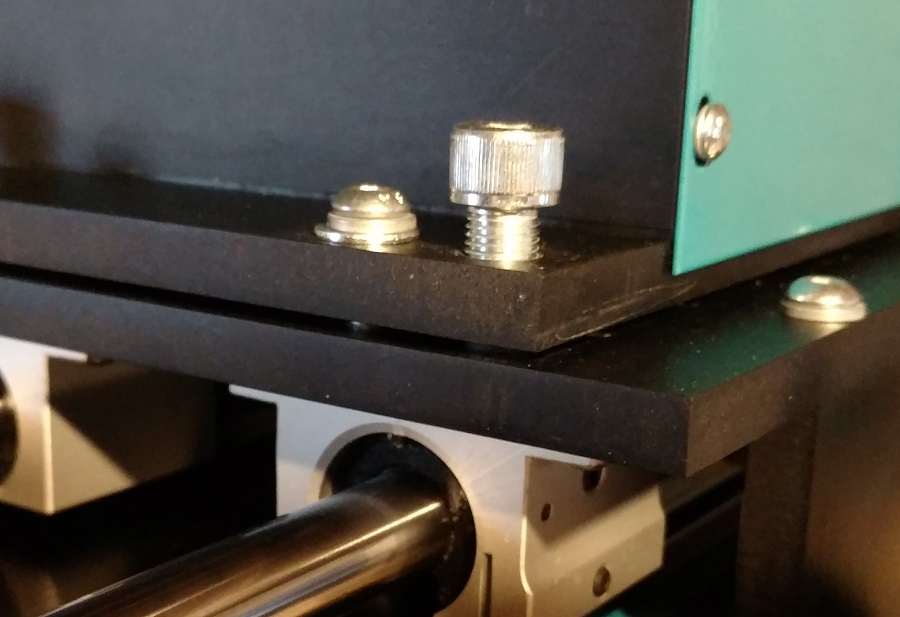

Leveling Mounting Feet

The lathe includes five adjustable leveling feet. These feet allow for mounting on an ordinary workbench thus eliminating the need to use a special leveling table. The three outside feet include mounting holes for securing the lathe to the work surface. You can even re-purpose the hardware used to secure the lathe feet to the shipping crate for your installation.

Scroll down for more Design Features

OR

Return

Corrosion Resistance

Special attention in the design phase was paid to atmospheric and galvanic corrosion. Durable powder coat paint and plating is used on exposed hardware and sheet metal components. Aluminum wear points are hard coated to military specification for a surface hardness that exceeds that of heat treated tool steel.

Scroll down for more Design Features

OR

Return

Fuse Status Indication

Electrical safety and protection is a mandatory design goal in our lathes. The lathe is equipped with fusing for both the main power input and the secondary motor drive electrical system. In the event of an electrical overload, lighted indicators allow the operator to know which fuse has blown and replacement is accomplished without needing to open any panel enclosures.

Scroll down for more Design Features

OR

Return

Ergonomic Design

Ergonomics and ease of use was a priority when designing the operator interface of the Model ADV. The control panel is precisely angled to allow comfortable use and good visibility while standing or sitting. Lighted, color coded, and organized button indicators assure intuitive operation. Audible tones assist in acknowledging button presses and alarm conditions.

Scroll down for more Design Features

OR

Return

Electrical Safety

Electrical safety is an important part of any machine design. The Model ADV is equipped with fusing for both the main power input and the secondary motor drive electrical system. A direct six point grounding harness is used to assure operator touch points maintain safety ground potential at all times. Each unit receives high current ground and high voltage insulation safety testing before shipment.

Scroll down for more Design Features

OR

Return

User Experience

Sometimes small things make a big difference. Our gear rack protection is designed to deflect debris and keep the operation of the tail stock smooth and clean. The sliding burner carriage has an adjustable drag and locking system. The lathe even has a handy padded shelf where you can store your cellphone.

Scroll down for more Design Features

OR

Return

Design Technique

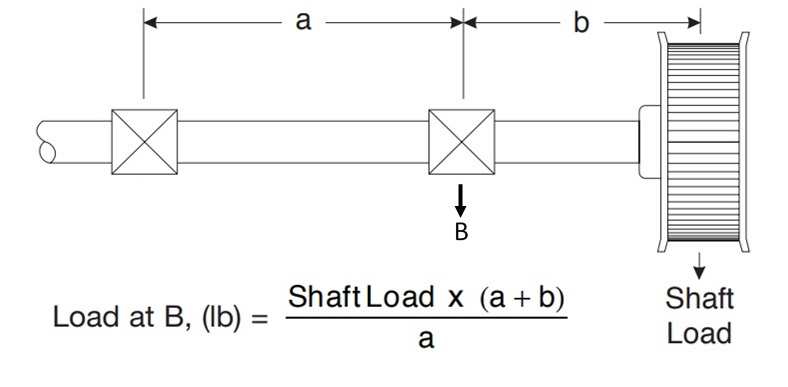

A robust product stems from more than just selecting solid components. The design of the Model ADV included worst case calculations of critical components and systems, 3D CAD modeling, and software simulation. This was followed up by extensive testing of the lathe design and performance. Verification measurements of parameters such as bearing, motor, and electronic enclosure temperatures assures the product will withstand the challenges of its application.